Welcome to Material Science Services:

Right Materials Ensure Right Products

Amorphous Content Testing (ACT®)

Amorphous Content Testing (ACT®) is a proprietary technology developed by M2M Pharmaceuticals that ensures reproducible and robust data across all inhaled APIs. Amorphous content determination is a regulatory requirement for inhaled APIs. In this platform, two decades of experience are embedded with highly sensitive, precise instrumentations. Quantification of the polymorphic forms can also be applied to oral solid dosage forms

Solid State Dossier (SSD™)

This platform ensures real-time data acquisition to enable quick decision making. Having 15 specialised techniques under one roof facilitates this. The objective here is to understand particle-particle interaction after processes (e.g. micronisation) over time, temperature and humidity. In other words, if you are developing inhaled products, when to formulate?

Crystalline in Amorphous Dispersion (CiAD™)

This platform enables detection and quantification of small levels of crystalline material in amorphous dispersions. Generally, Raman Spectrophotometry and X-ray powder diffraction are sensitive and robust with crystalline substances, therefore adopting chemical imaging by Raman and diffraction analysis by X-ray are the first preferred techniques in this platform.

Surface Coverage (Surfage™)

This is a dedicated platform for understanding surface coverage of excipients in formulations. For example, how much coverage is achieved by Magnesium Stearate in a dry powder blend. Five specialised techniques are employed here; some are qualitative (ToFSIMS and SEM-EDX), some are quantitative (XPS and DCA) and chemical imaging by Raman.

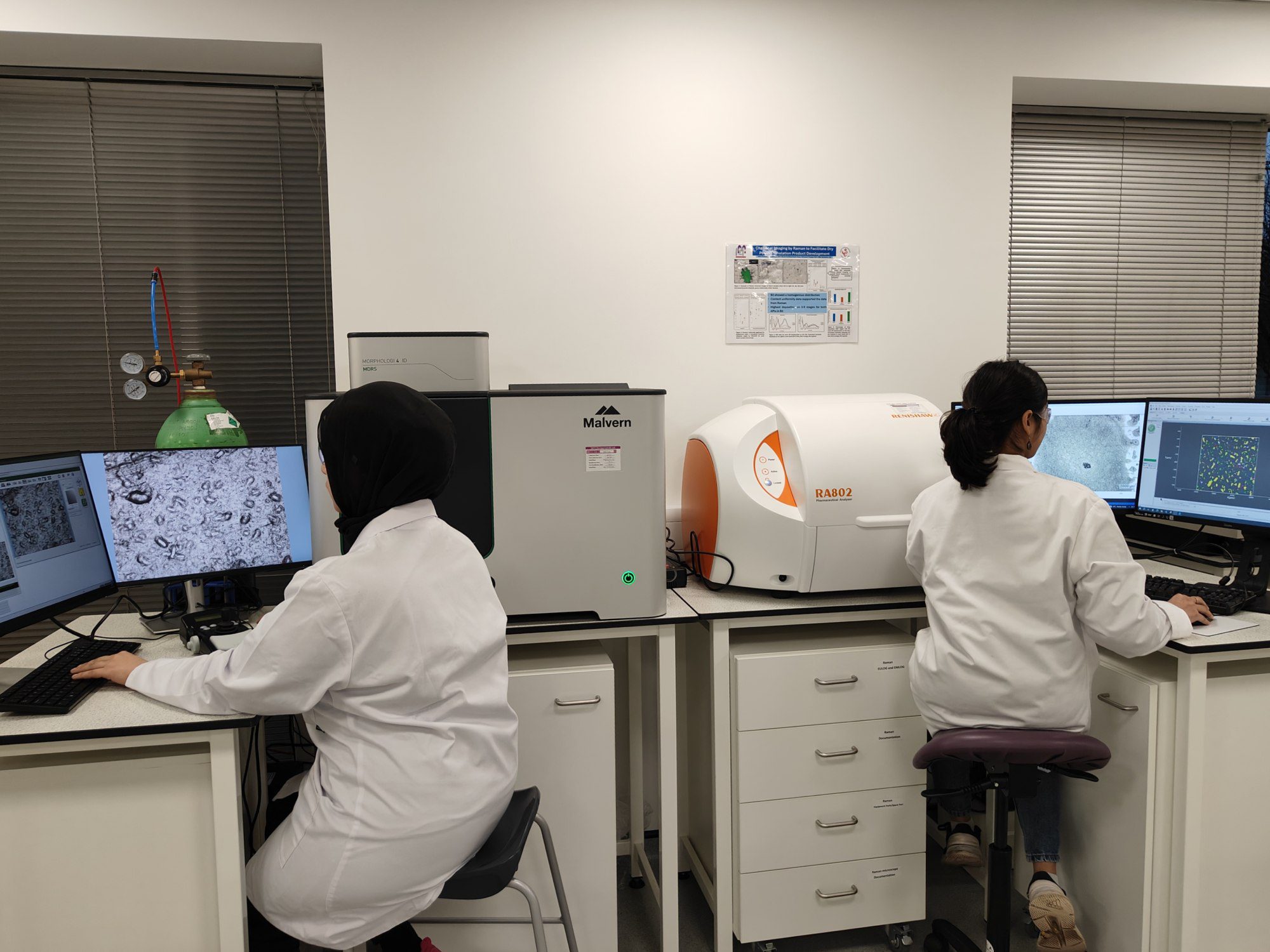

Material Science Laboratory:

This has 1100 sqft of space and comprises into four different zones with specialised instrumentations.

Calorimetric Zone:

- TAM2277 (Multichannel Solution Calorimeters)

- TAMIII (Multichannel Solution Calorimeters)

- Perfusion Calorimeter

- Microcalorimetry

Advanced Characterisation Zone:

- 2 x DVS (+ organics)

- XRPD

- TGA

- DSC

- iGC-SEA

Particles Zone:

- Mastersizer 3000 (dry + wet)

- Sympatec (dry + wet)

- BET-SSA

- Pycnometer

- PLM

Welcome to Product Development:

The 600 sqft of space is occupied by instruments to carry out processes, analyticals and stability.

Processes Zone:

- Air Jet-Milling

- Micronisation

- Ball milling (cryo)

- Spray Drying (+ organics)

- Rotary Evaporation

- Freeze Drying

- Turbula Blender

Analytical Zone:

- NGI, rNGI, FSI, CI, MSLI

- HPLC

- Microbalance

Stability Zone:

- R&D Stability in four ovens at 25°C/60%RH, 30°C/65%RH, 40°C/75%RH and 80°C

Develop Inhale Products (DiP™)

M2M provides inhaled product development services with its in-house capabilities and decades of experience using this DiP platform.

In-House Routine Analysis

- SolCal

- Perfusion

- Microcalorimetry

- DVS

- XRPD

- TGA

- DSC

- iGC-SEA

- PSD (Wet and Dry by Mastersizer and Sympatec)

- Pycnometer

- BET Surface Area

- Morphologically Derived Raman Spectroscopy

- Raman Chemical Imaging by Renishaw RA802

- PLM

- micro-CT

- Excipient compatibility using TAM and HPLC

- Air-Jet Milling

- Ball-Milling (cryogenic)

- Spray Drying (aqueous, organic)

- Freeze-Drying

- Rotary Vaporation

- Blending

- NGI testing

- HPLC

Other Routine Services with Collaboration

- SEM: We provide 24-48 hours SEM imaging service with at least 10 images at different magnifications.

- Hot-stage Microscopy

- TEM and Cryo-TEM

- AFM

- ToF-SIMS

- XPS

- DCA

- SEM-EDX

- Analytical Ultra-centrifugation (AUC)

- DSC-XRD

- DVS-NIR

- NMR, Mass Spec & Spectroflurometry

- FTIR, Imaging, UV-Vis etc.

- CHN Analysis

- Total carbon and TOC measurement

- Water Activity Measurement

- Vitamins, Nutritional testing, Lipid profiles, Protein Profiles, Microbiological, Aerobic counts etc.